In today’s rapidly evolving technological landscape, smart manufacturing has emerged as a game-changer in the industrial sector. With the advent of Industry 4.0, which refers to the fourth industrial revolution characterized by automation and data exchange, smart manufacturing has become an integral part of modern production processes.

The Essence of Smart Manufacturing in Industry 4.0

Smart manufacturing leverages advanced technologies such as artificial intelligence (AI), Internet of Things (IoT), big data analytics, and robotics to optimize efficiency, productivity, and quality within factories. It involves interconnected systems that communicate with each other seamlessly, enabling real-time monitoring and control over various aspects of production.

JVTECH: Pioneering Smart Manufacturing Solutions

One notable player at the forefront of smart manufacturing is JVTECH – a leading technology company specializing in innovative solutions for industry 4.0 transformations. By integrating cutting-edge technologies into their products and services, JVTECH empowers manufacturers to streamline operations and achieve higher levels of performance.

JVTECH offers a comprehensive range of solutions tailored to meet specific needs across diverse industries. Their expertise lies in developing intelligent systems that enable predictive maintenance, remote monitoring, and optimization through AI-driven algorithms.

Overmolding Medical: A Revolutionary Application

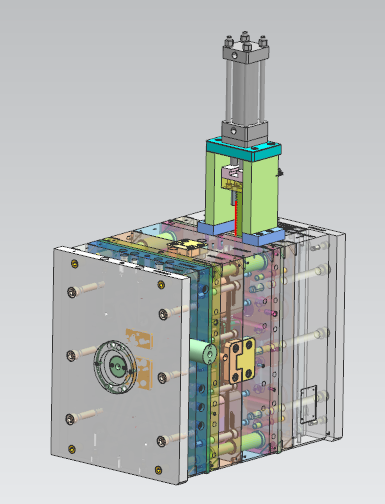

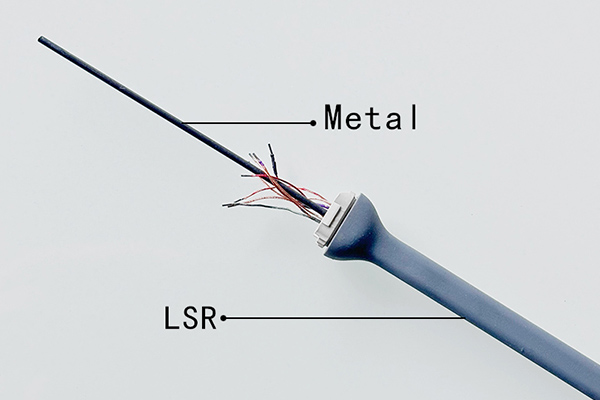

An exemplary application showcasing the power of smart manufacturing is overmolding medical devices – a process where two or more materials are combined during injection molding to create complex medical components with enhanced functionality.

This technique not only improves product durability but also enables precise customization according to patient requirements while maintaining strict safety standards. Through smart manufacturing practices facilitated by Industry 4.0 technologies like IoT sensors embedded within molds or machines, manufacturers can monitor and control the overmolding process in real-time, ensuring consistent quality and reducing defects.

Furthermore, by leveraging big data analytics, manufacturers can gain valuable insights into production trends and make data-driven decisions to optimize processes. This results in reduced costs, increased productivity, and improved patient outcomes.

The Future of Smart Manufacturing in Industry 4.0

As smart manufacturing continues to evolve within the framework of Industry 4.0, its potential for revolutionizing the industrial landscape is boundless. The integration of AI-powered systems will enable factories to become more autonomous and adaptive than ever before.

With advancements like collaborative robots (cobots) working alongside human operators seamlessly or predictive maintenance algorithms preventing costly breakdowns through proactive identification of issues, smart manufacturing promises a future where efficiency reaches unprecedented heights while maintaining high-quality standards.

In conclusion, smart manufacturing in industry 4.0 represents a paradigm shift that empowers industries with intelligent technologies to enhance productivity, reduce costs, improve product quality, and drive innovation. Embracing these transformative practices is crucial for businesses aiming to thrive in an increasingly competitive global market.